HYDRAULIC TORQUE WRENCHES: TYPES, PUMPS AND HYDRAULIC EQUIPMENT

Hydraulic Torque Wrenches: Types, Pumps and Hydraulic Equipment

In industrial applications, the assembly and disassembly of large and heavy machinery frequently necessitates using tools that can generate exact torque. Hydraulic Torque Wrenches come in handy here. These extraordinary tools deliver precise torque, assuring the tightest fastenings in crucial industries such as manufacturing, construction, and oil & gas. Let us look at Hydraulic Torque Wrenches, their different varieties, the hydraulic pumps that power them, and the associated hydraulic equipment that takes industrial activities to new heights.

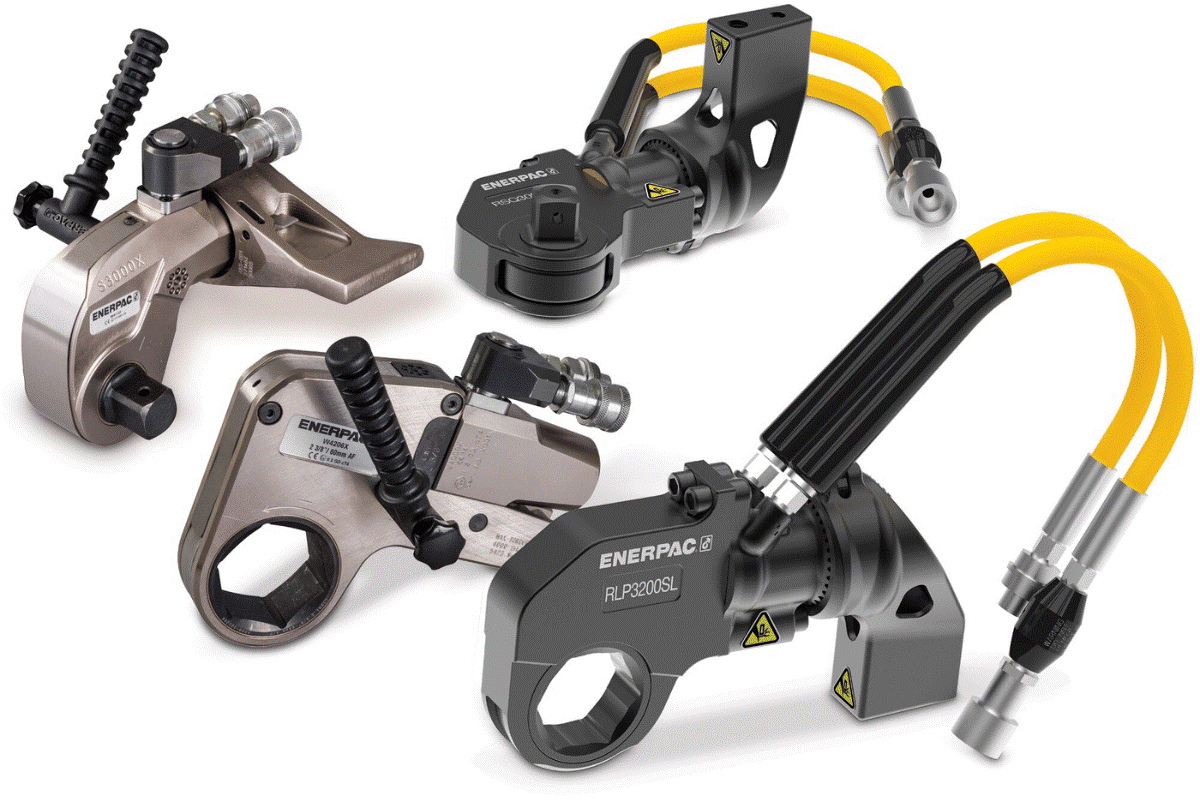

Different Types of Hydraulic Torque Wrenches

Hydraulic Torque Wrenches are of several varieties, each customized to unique uses and operational needs. Let's look at three common types:

Square Drive Hydraulic Torque Wrenches: These wrenches are versatile and used for various tasks. They have replaceable heads, giving them variety and adaptability. Square drive hydraulic wrenches are ideal for a wide range of fasteners and are known for their precision.

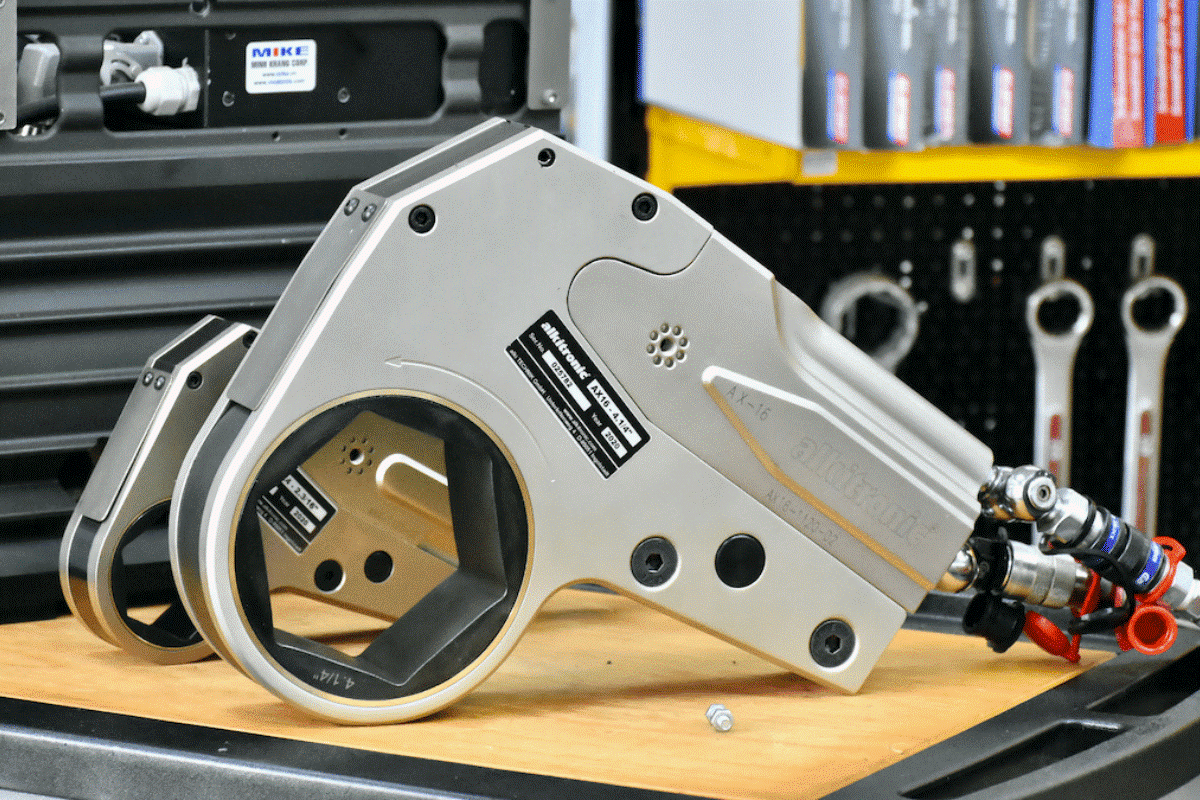

Low Profile Hydraulic Torque Wrenches: Low profile wrenches work well in limited spaces or difficult access. They are small and can fit into small locations, making them useful in industries like aerospace and automotive manufacturing.

Hollow Plunger Hydraulic Torque Wrenches: These wrenches are handy when an extended bolt protrudes through the fastener. Hollow plunger wrenches work well with longer bolts and have a lengthy reach.

The Function of Hydraulic Pumps

Hydraulic pumps in hydraulic torque wrenches generate the force required for exact torque application. Hydraulic pumps are of two types:

Electric Hydraulic Pumps: Interior areas with convenient access to electricity utilize electric hydraulic pumps. These pumps generate accurate torque by providing steady and controlled hydraulic pressure.

Air Hydraulic Pumps: Air-powered hydraulic pumps are appropriate for applications where electricity is not available. They create hydraulic pressure using compressed air, making them suited for outdoor and isolated work areas.

The application, accessible power sources, and climatic factors influence the decision between electric and air hydraulic pumps.

Hydraulic Torque Accessories

To expedite operations, several types of hydraulic equipment and accessories work in combination with Hydraulic Torque Wrenches.

Hydraulic Hoses: The hydraulic hoses carry hydraulic fluid from the pump to the torque wrench. They are available in various lengths and handle high pressure.

Gauges and Pressure Controllers:It is critical to monitor hydraulic pressure to achieve proper torque. Pressure gauges and controllers aid in maintaining desired pressure levels, resulting in consistent outcomes.

High-Quality Hydraulic Fluid: The hydraulic fluid utilized in the system must be of high quality. The proper fluid ensures that the hydraulic torque wrench operates smoothly and efficiently.

Conclusion

Hydraulic torque wrenches have transformed precision torque applications in crucial sectors. These tools are versatile and ideal for a wide range of applications since they use various types of wrenches, hydraulic pumps, and associated equipment. To address the different needs of modern enterprises, AFH Tools, a leading name in industrial solutions, offers a wide variety of Hydraulic Torque Wrenches. The company's Hydraulic Torque Wrenches are engineered for precision, accuracy, and longevity, making them ideal for industries where bolt and fastener torque is crucial. Consider the Hydraulic Torque Wrenches offered by AFH Tools if you're serious about obtaining precision and safety in your industrial activities.