HOW TO CHOOSE THE RIGHT MAG DRILL FOR THE JOB?

How to Choose the Right Mag Drill for the Job?

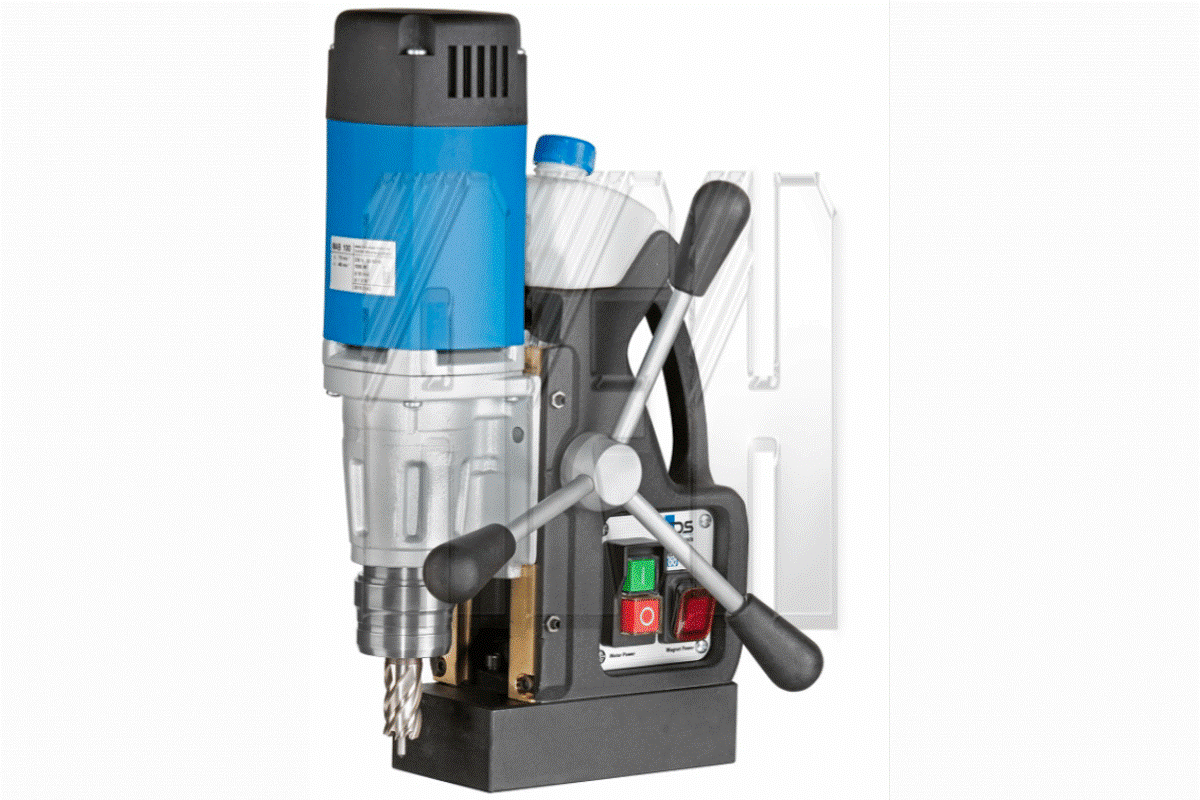

When it's time to purchase a magnetic drilling machine, often referred to as a mag drill, it's crucial to choose the right one that fits your needs. Mag drills are indispensable for anyone involved in the production, installation, or modification of steel and metals. They come in various sizes, power levels, and weights, directly influencing the diameter of the holes they can drill and the thickness of the material they can handle.

Given the vast array of mag drills available, choosing the right one can be overwhelming. There are drills designed for simple hole-making on flat plates, low-profile drills for tight spaces, and ATEX-certified drills for hazardous environments like mining.

Here’s a guide to help you narrow down your options when looking for magnetic drilling machines in Dubai.

Determine the Maximum Hole Diameter and Material Thickness:

These two dimensions will dictate the minimum size and power of the mag drill required. Most mag drills are designed to use annular cutters, but many can also accommodate solid twist drill bits.

Number of Holes to Drill:

Manual feed drills are suitable for fewer holes. However, for drilling numerous holes, a semi-automatic mag drill is better as it reduces operator fatigue and extends cutter life.

Coolant System:

Always opt for a mag drill with an integrated coolant system. Proper cooling prevents annular cutters and drill bits from dulling quickly. Aerosol spray or paste coolants are preferable for vertical or overhead drilling.

Material Type:

Different materials require different RPMs. Harder materials and larger diameter cutters should be drilled at lower RPMs to prevent overheating. Mag drills with variable speed motors and multiple ratio gearboxes are advantageous.

Space Constraints:

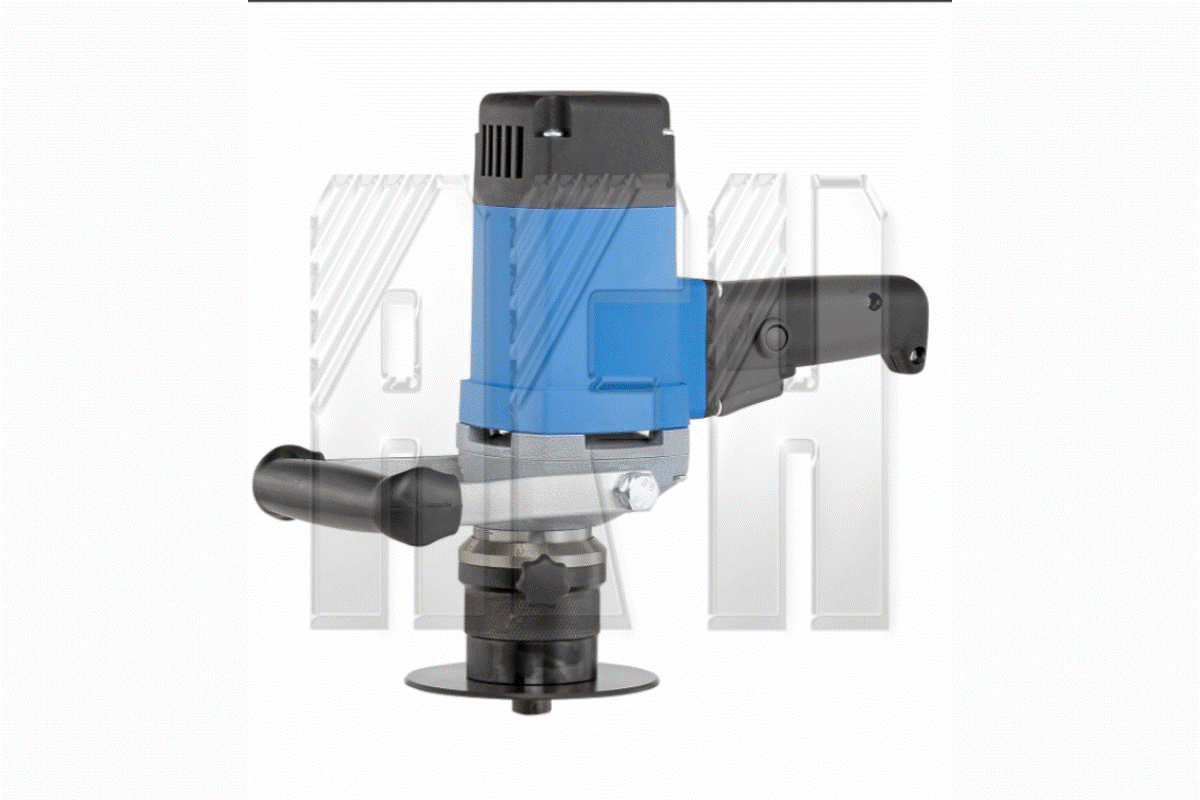

For tight spaces or elevated work, such as truck frames or bridge construction, a low-profile, lightweight drill is ideal.

Drilling Orientation:

Ensure the mag drill comes with safety chains or straps for vertical or overhead drilling. These safety features are crucial to prevent accidents in case of power failure.

Necessary Accessories:

Consider if you need to use twist drill bits, tap holes, countersink, or drill in non-ferrous materials. Ensure the mag drill you choose can accommodate the required accessories.

Ease of Use:

Access to controls should be easy regardless of the drill's orientation. This factor is often overlooked but is essential for operational efficiency.

Safety Features:

Always follow the operator's manual and use securing chains or straps. The drill should have integrated safety features like a swarf guard and magnetic holding power controls such as MFSC (Magnetic Field Shape Control) and MPAC (Magnetic Power Adhesion Control).

When it comes to finding the best magnetic drilling machines in Dubai, AFH Tools offers a comprehensive range of high-quality German-made mag drills from BDS Machines tailored to various applications. Our products ensure ease of use, robust safety features, and optimal performance, making us a top choice for industry professionals.

Focusing on these critical factors can help you confidently select the right magnetic drilling machine to meet your specific needs and enhance your operational efficiency. Trust AFH Tools for reliable and efficient solutions in magnetic drilling machines in Dubai.

If you have any questions, you can contact us at +971 25566704, and we'll be happy to help.