FROM BEGINNER TO EXPERT: A COMPREHENSIVE GUIDE TO USING MAGNETIC DRILLING MACHINES

From Beginner to Expert: A Comprehensive Guide to Using Magnetic Drilling Machines

Magnetic drilling machines are essential for businesses requiring precise, efficient metal hole-making. Understanding the ins and outs of these devices is critical for attaining the best outcomes, whether you're a rookie or an experienced professional. AF Hussain, a well-known supplier of magnetic drilling machines in Dubai, offers complete instructions to assist you in progressing from novice to expert in using these powerful instruments.

Magnetic Drilling Machines in Dubai: An Overview

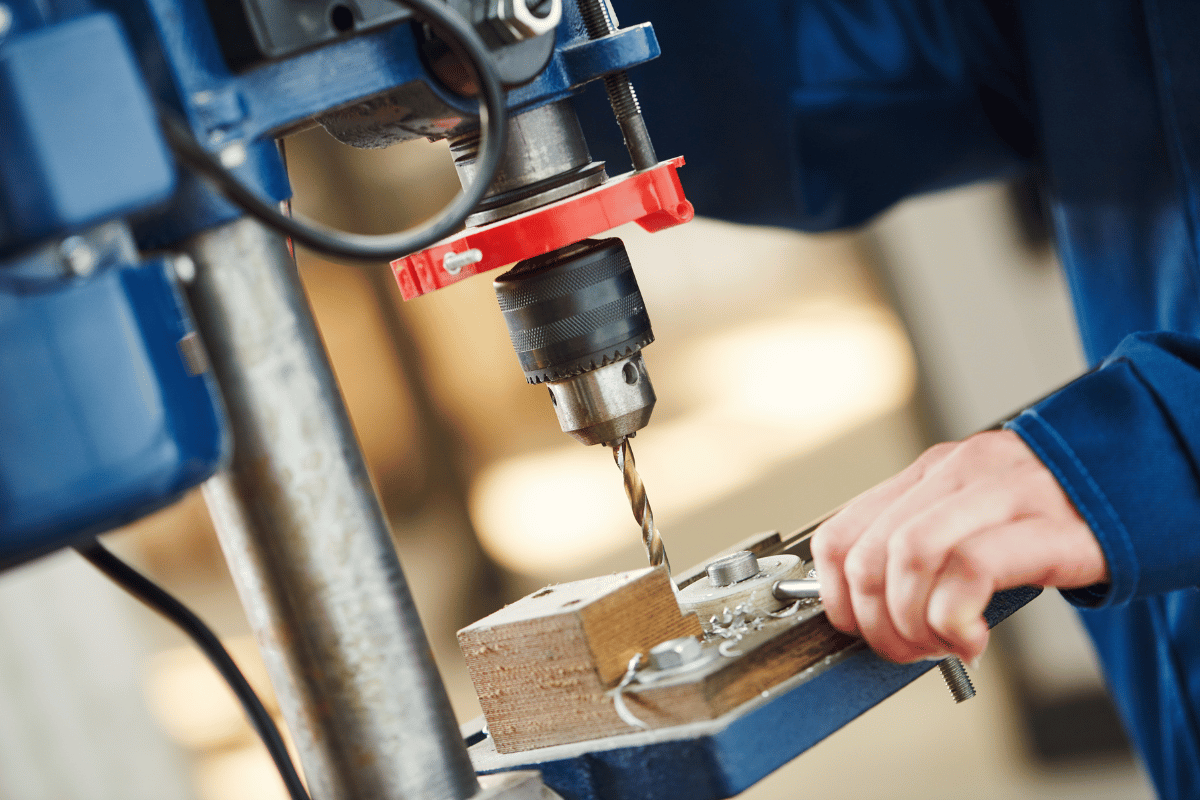

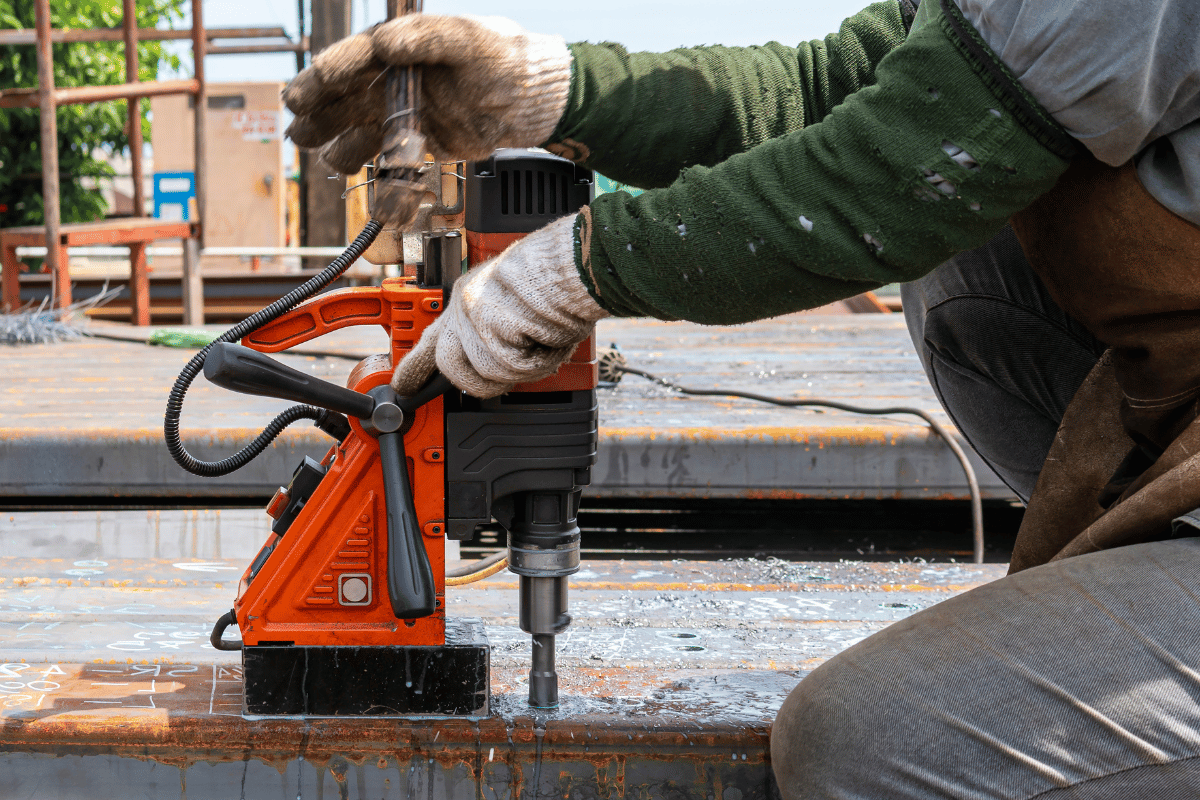

Magnetic drilling machines are specialist instruments to make precise holes in metal surfaces. These machines include electromagnetic bases that attach to metal surfaces securely, providing a steady platform for drilling operations. These machines, equipped with a drilling motor and a cutter, provide the benefit of accurate, burr-free hole-making, making them indispensable in the building, manufacturing, and metalworking industries.

Getting Started: Putting Your Magnetic Drilling Machine Together

- 1.Choosing the Right Machine: Select a magnetic drilling machine that meets your requirements, considering parameters such as drilling capacity, cutter size, and portability. In Dubai, AF Hussain provides a variety of magnetic drilling equipment to meet various industrial needs.

- 2.Workspace Preparation: Ensure the work area is clean, flat, and dirt-free. Place the magnetic drilling machine on the metal surface and activate the electromagnetic base for a firm grip.

- 3.Workpiece Securing: Use appropriate clamping devices to keep the workpiece firmly in place. This ensures stability during the drilling process.

Understanding Operation Techniques

- 1.Operating the Machine: Become acquainted with the machine's controls and functions. To suit the material being drilled, adjust the drilling speed and depth. For best results, always follow the manufacturer's instructions.

- 2.Drilling Techniques: When drilling, use consistent pressure. Allow the cutter to work without interfering, creating a smooth and exact hole.

- 3.Coolant Usage: Use coolant or lubricants as directed to improve drilling efficiency, prevent heat buildup, and extend cutter life.

Precautions for Safety

- 1.Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and hearing protection, to protect yourself from potential threats.

- 2.Machine Inspection: Inspect the machine regularly for evidence of damage, wear, or loose components. Before operating the unit, resolve any faults as soon as possible.

- 3.Emergency protocols: Become familiar with emergency shut-off protocols and first-aid measures in case of an accident or unforeseen incident.

Advanced Performance Techniques

- 1.Tool Maintenance: Regularly clean and maintain the machine and cutting tools to guarantee optimal performance and longevity.

- 2.Advanced Drilling Techniques: Investigate advanced drilling techniques and accessories that can improve the machine's capabilities, such as annular cutters, tapping attachments, and depth stop accessories.

- 2.Advanced Drilling Techniques: Investigate advanced drilling techniques and accessories that can improve the machine's capabilities, such as annular cutters, tapping attachments, and depth stop accessories.

- 3.Continuous Learning: Stay current on the newest innovations in magnetic drilling technology by participating in training programs, reading industry publications, or attending seminars to hone your skills and expertise.

Conclusion

Understanding how to utilize magnetic drilling equipment is necessary for professionals in various industries. AF Hussain's magnetic drilling machines in Dubai provide dependability, precision, and efficiency for various industrial applications. Following this comprehensive instruction, whether you're a beginner or an expert, will empower you to grasp the full potential of magnetic drilling equipment, ensuring precise and efficient hole-making operations on metal surfaces.