ADVANTAGES AND DISADVANTAGES OF LATHE MACHINE

Advantages and Disadvantages of Lathe Machine

Numerous businesses, ranging from modest shops to expansive manufacturers, require lathe machines. They are utilized to form and shape various materials into the desired shapes and sizes. However, what is a lathe machine and what are its advantages and disadvantages? Let's take a peek.

These instruments, which were created by Conrad Bahr in 1918, have been in use ever since the early 20th century.

How Does It Work?

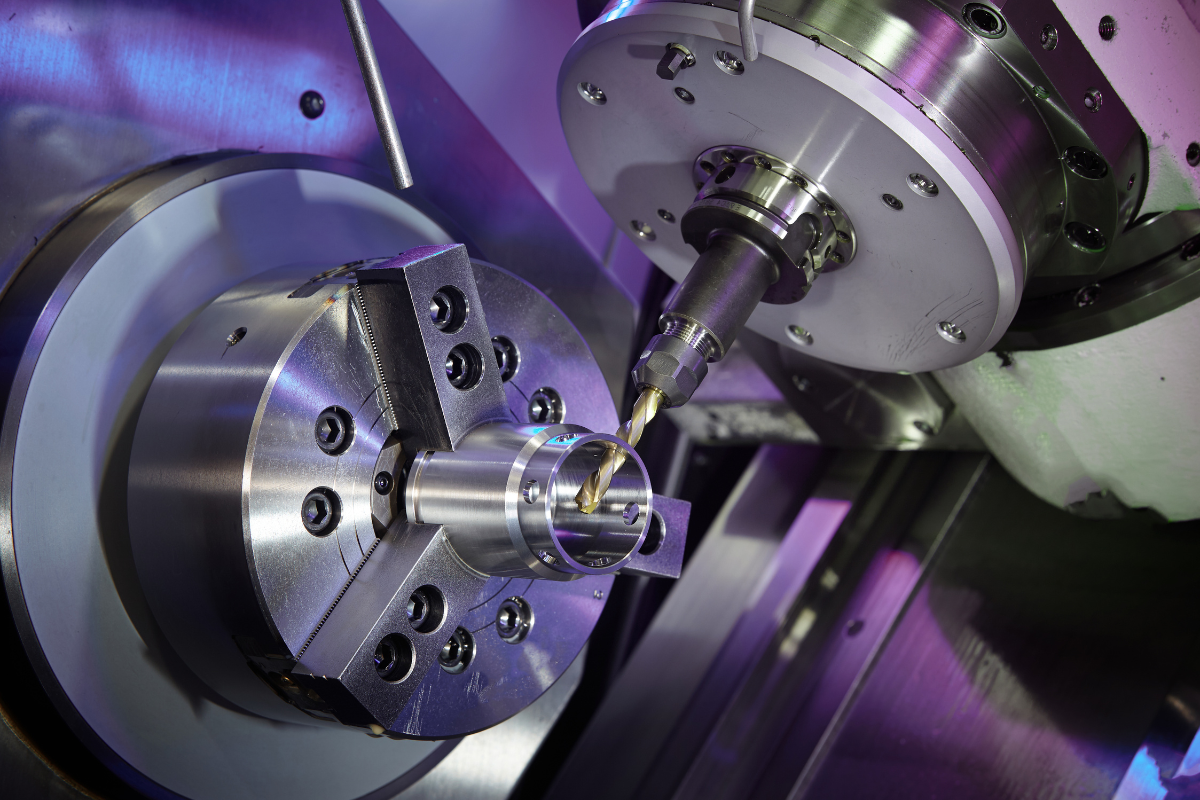

A lathe machine is a precision cutting device that rotates the material being worked on while holding a cutting instrument against it. Certain portions can then be removed by moving the cutting instrument parallel or at an angle to the axis of the rotating material. This enables extremely accurate shaping and forming of the material. In addition to cutting threads into parts and performing knurling operations, the lathe machine is even more versatile in its applications.

Advantages of Lathe Machines

The greatest benefit of using a lathe machine is that it can produce parts with high precision and rapidity. This substantially reduces production times, thereby saving businesses time and money. Due to their ability to cut threads into parts, machines can produce complex parts rapidly without sacrificing accuracy or quality. Lastly, because they are simple to operate, minimal training is required, making them ideal for small businesses with limited resources.

Higher Productivity

One of the primary benefits of lathe machines is their ability to boost productivity. This is due to the fact that lathe machines are designed to perform a variety of operations, such as cutting, sanding, and piercing. Consequently, lathe operators are able to complete tasks more swiftly and efficiently than those using hand tools.

Superior Accuracy

Another benefit of lathe machines is that they are more precise than manual tools. This is due to the fact that lathe devices enable more precise cuts and drilling, which can enhance the quality of the final product.

Improved Security

Additionally, lathe devices can contribute to a safer workplace. This is due to the fact that lathe machines are designed to reduce the likelihood of injury by reducing the need for employees to handle sharp tools. In addition, lathe machines include safety features that can help prevent accidents.

Reduced Expenses

Additionally, lathe devices can reduce costs in the workplace. This is due to the fact that lathe machines are designed to be more efficient than manual tools, thereby reducing the amount of time and materials required to complete a task. In addition, lathe machines require less upkeep than manual tools, which can further reduce costs.

Superior Quality

Additionally, lathe devices can enhance the quality of the final product. This is because lathe machines allow for more precise cutting and drilling, which can improve the overall appearance and functionality of the finished product.

Disadvantages of Lathe Machines

Due to its high precision, the primary disadvantage of using a lathe machine is that it requires frequent maintenance. This necessitates routine cleansing and lubrication to ensure continued functionality. Due to the high precision of these machines, they tend to be quite expensive, making them less desirable for smaller enterprises that can not have the funds required for purchase or maintenance.

High starting price

The initial cost is one of the greatest disadvantages of lathe devices. Lathe machines can be prohibitively expensive if you are just starting a business or need one for a personal endeavour.

Requires Knowledgeable Operators

Another disadvantage of lathe machines is that expert operators are required. Although lathes are simple to operate, there is a learning curve. If no one on your staff has experience operating a lathe, you will likely need to employ someone or take the time to learn how to operate the machine.

Exceptional Applications

Similarly, lathe machines have limited applications. While they are very versatile and can be used for a variety of projects, there are some that they cannot complete. If you have a specific project in mind, you should investigate whether or not a lathe machine is capable of completing it before making a purchase.

Can Be Hazardous

If not used appropriately, lathe machines can also be hazardous. Due to the fact that lathes contain rotating components, there is a danger of injury if the operator is not cautious. Be sure to read the safety instructions included with your lathe machine and take all precautions necessary before using it.

Requires Regular Maintenance

Lastly, lathe devices require routine maintenance in order to function properly. If you adhere to the machine's maintenance schedule, it can break down and become usable.

Conclusion

A lathe machine is an indispensable instrument in numerous industries and manufacturing procedures. It is a versatile machine that can perform a variety of operations with high precision and accuracy, including drilling, cutting, and rotating. However, as discussed in this blog, there are disadvantages to using a lathe machine, including its high cost, complex setup, and maintenance requirements. If you are searching for a high-quality lathe machine in Dubai, you can rely on AF Hussain. They offer a variety of lathe machines designed to satisfy the requirements of various industries and applications. With their knowledge and experience, they can assist you in selecting the ideal lathe machine for your business and provide the necessary support and maintenance services to keep it operating efficiently. Contact AF Husain immediately to improve your manufacturing processes with a dependable and effective lathe machine.